POLO-KAL 3S MONOTEC

POLO-KAL 3S MONOTEC

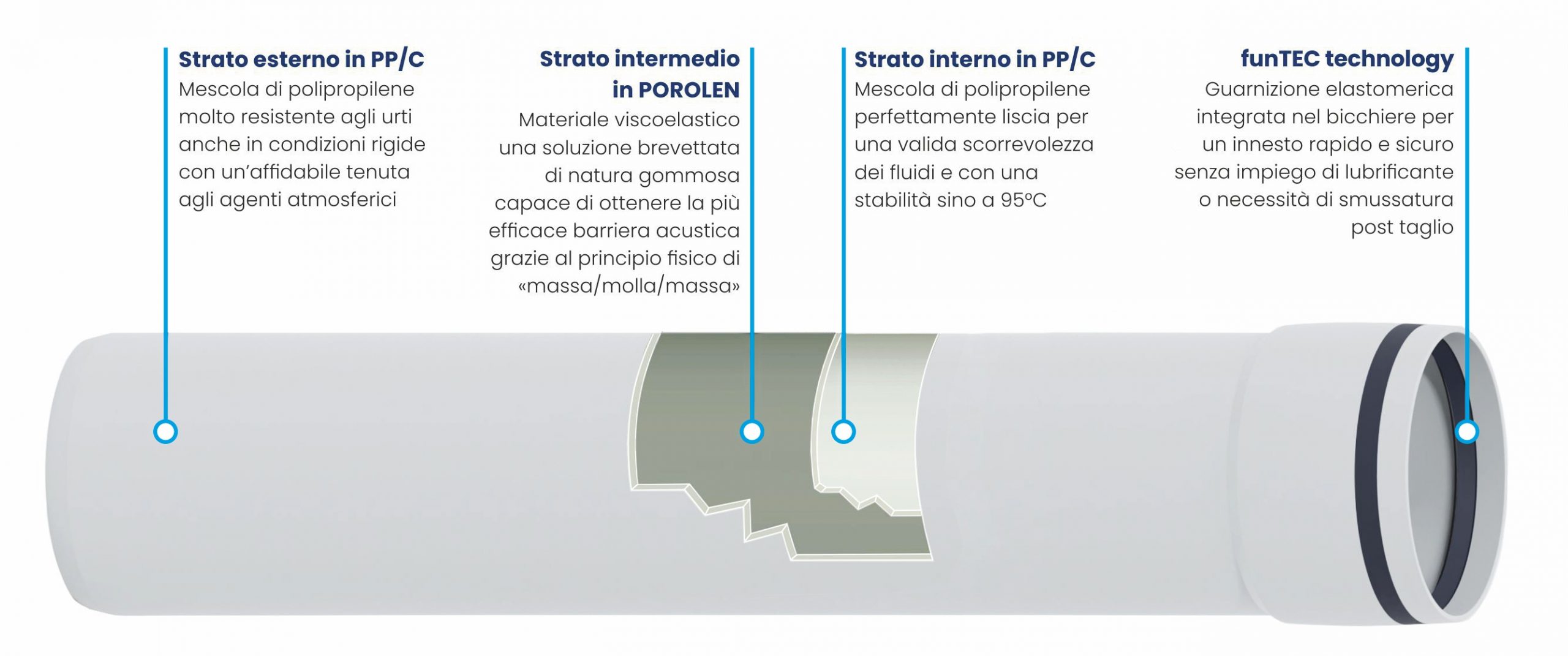

Dal 1990 il primo sistema fonoassorbente che adottò il principio di “massa / molla / massa” applicandolo ad una tubazione di scarico in polipropilene (PP) di colore bianco RAL 7035. Una gamma con diametri da 50 a 160 mm. composta da tubazioni coestruse a 3 strati con lo strato intermedio in “Porolen” (un particolare e brevettato materiale di natura gommosa) e raccordi rinforzati con cariche minerali (MV) che conferiscono al sistema le più elevate performance d’isolamento acustico, resistenza all’impatto , alla corrosione, all’abrasione e all’aggressione di sostanze chimiche disciolte negli scarichi civili ed industriali. Dal 2024 anche per POLO-KAL 3S MT è stata applicata la guarnizione “Monotec”. Si tratta dell’esclusiva tecnologia produttiva “funTEC” che permette di realizzare la guarnizione di tenuta direttamente stampata nel bicchiere. Questo permette di ottenere innumerevoli vantaggi:

- Innesto senza impiego di lubrificanti

- Innesto senza la necessità di smussare il tubo tagliato

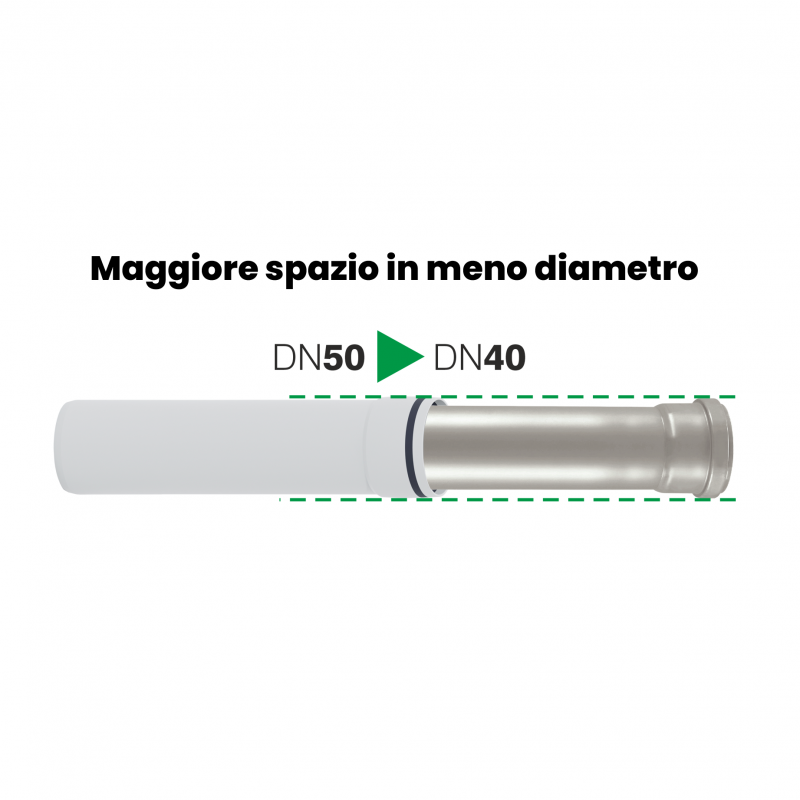

- Riduzione dell’ingombro del bicchiere

- Riduzione di almeno il 50% dei tempi necessari alla posa in opera di una rete di scarico

Sistema per lo scarico dei reflui conforme alla EN 1451-1 in Classe B (all’interno del fabbricato) idoneo per impianti in edifici nei quali è richiesto un elevato comfort acustico a destinazione residenziale, industriale e commerciale, pubblici e ricettivi come ospedali, case di riposo e RSA, alberghi, scuole, luoghi di culto.

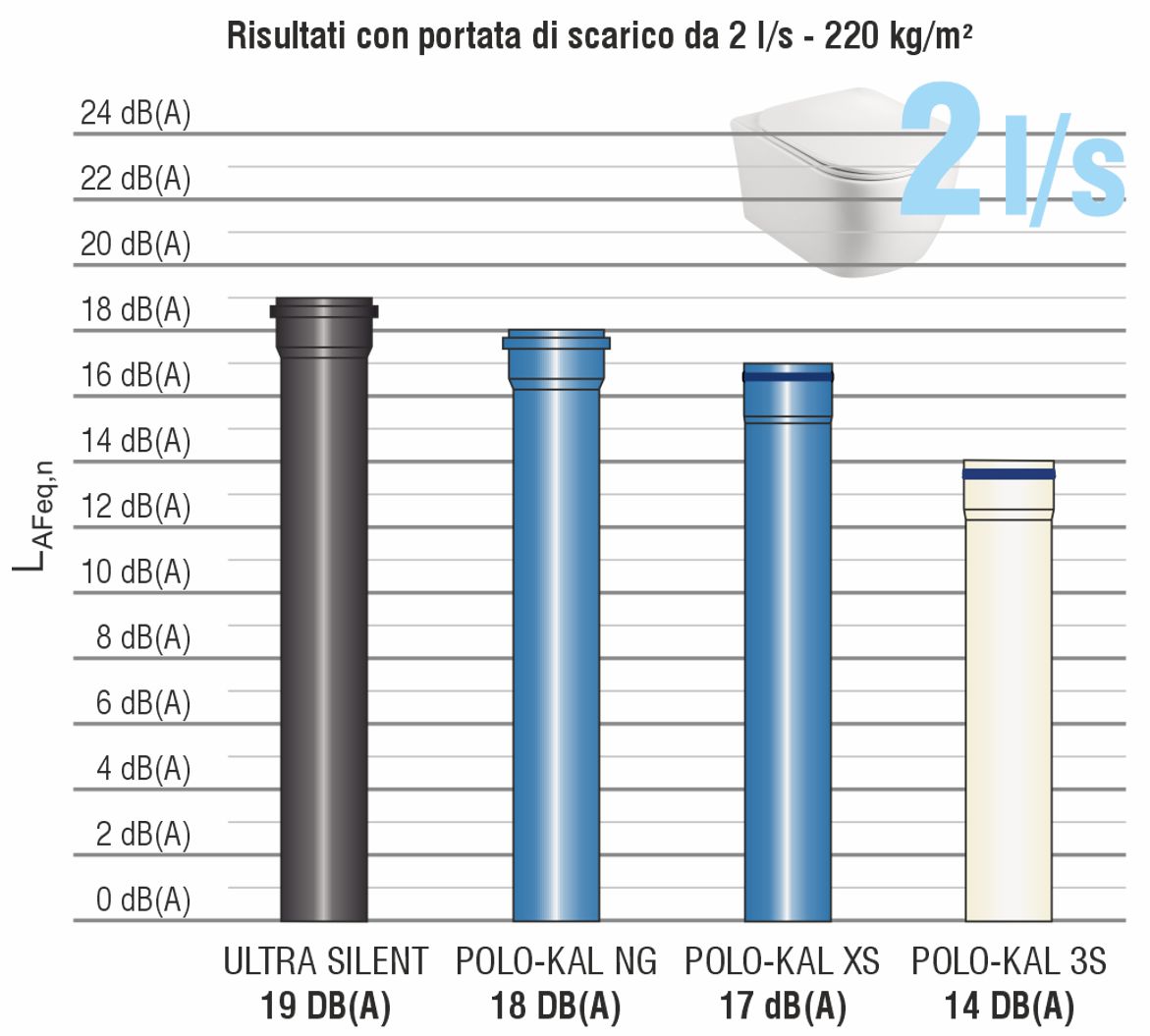

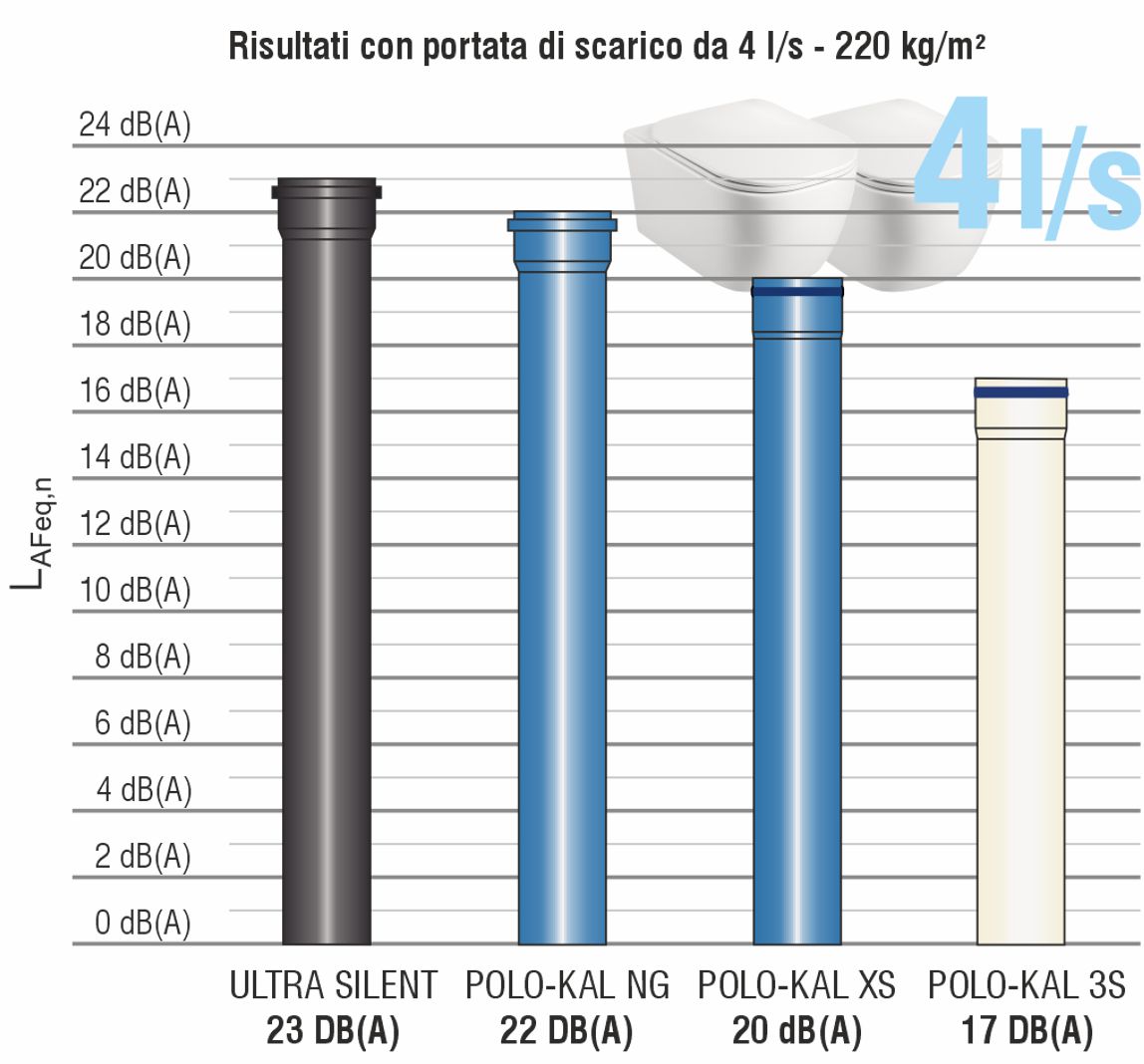

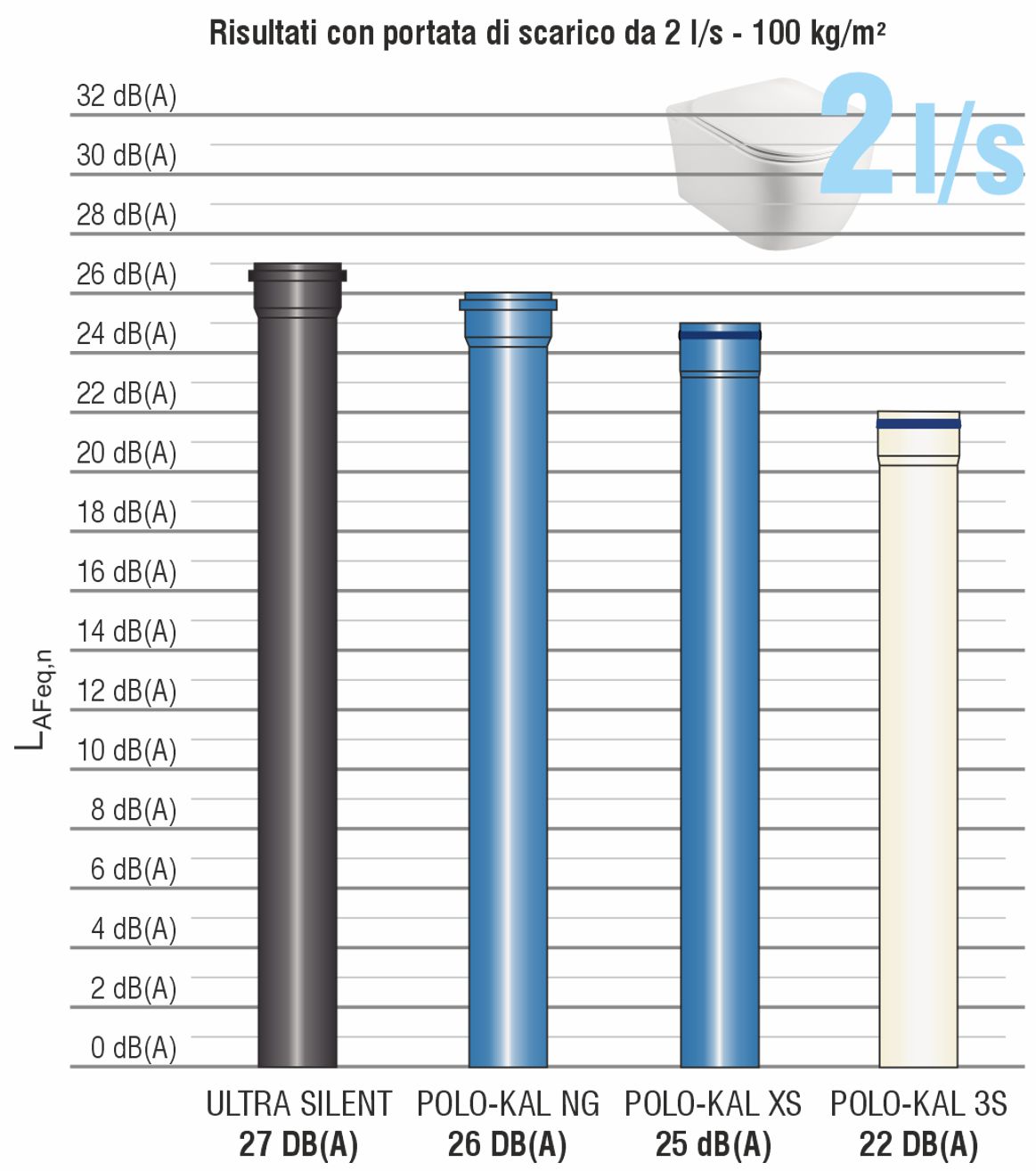

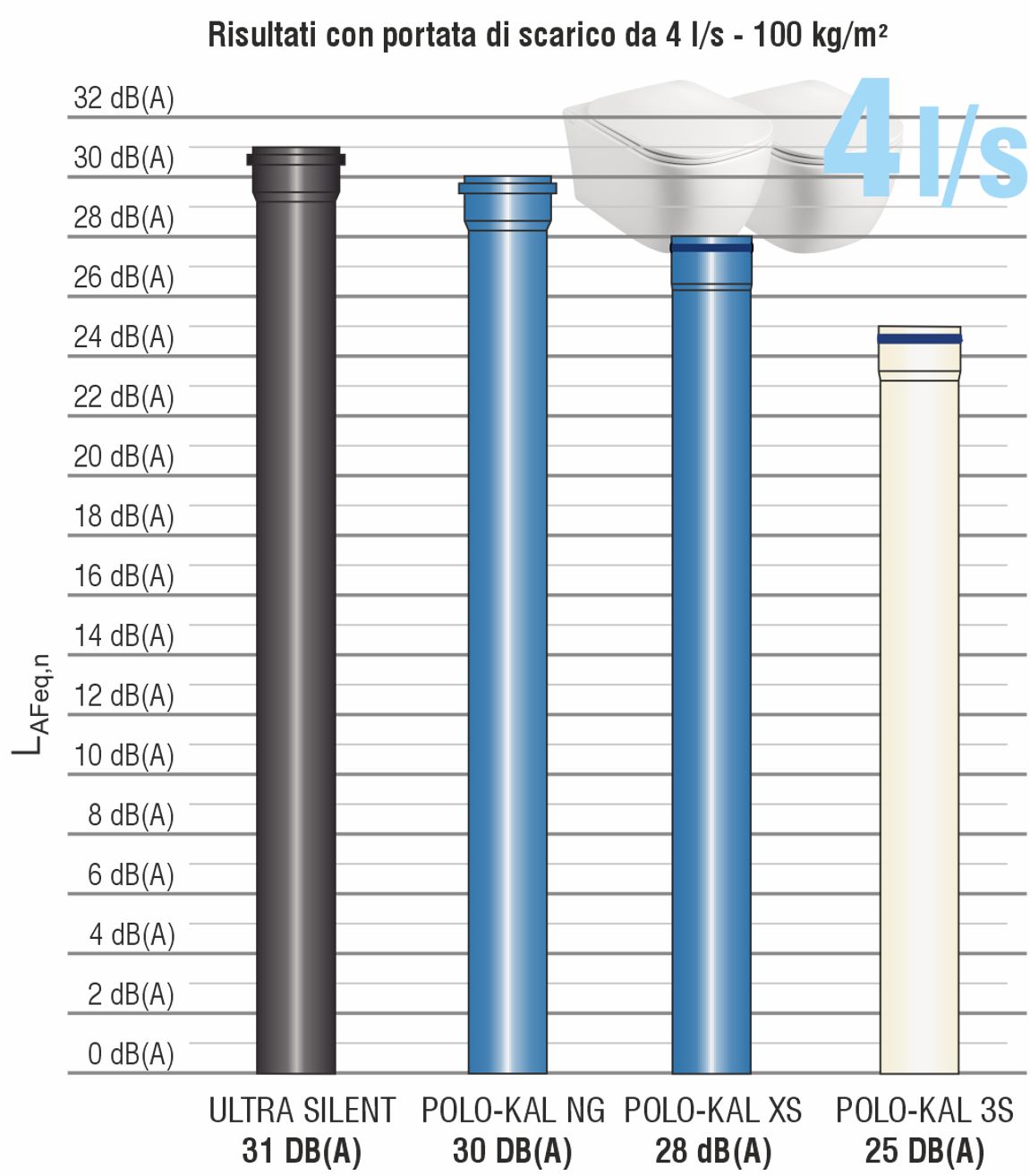

Il sistema di scarico idrico POLO-KAL 3S MT può essere dimensionato secondo quanto prescritto dalla norma di riferimento progettuale, la UNI EN 12056-2. Secondo tali prescrizioni, per la realizzazione della ventilazione del sistema di scarico, possono essere utilizzati tubi e raccordi del sistema POLO-KAL 3S MT o di altri sistemi di scarico offerti da Bampi e, in alternativa, valvole di ventilazione BAMVENT. In osservanza al DPCM 5/12/1997 sui requisiti acustici passivi all’interno degli edifici (Legge vigente in Italia), il sistema di scarico idrico POLO-KAL 3S MT offre le più elevate prestazioni di fonoisolamento certificate in accordo alla EN 14366 presso l’Istituto Fraunhöfer di Stoccarda.

Sistema pesante da installare tramite giunzione con innesto, assicurata da guarnizione elastomerica. La connessione con bicchiere garantisce l’adeguato spazio per eventuali dilatazioni dell’impianto con una tenuta affidabile e garantita nel tempo. Il sistema in polipropilene POLO-KAL 3S MT è compatibile alla connessione con altri materiali plastici in PP/PE-HD/PVC nei diametri standard.

La tecnologia applicata al sistema POLO-KAL 3S MT permette di ridurre almeno del 50% i tempi d’installazione, grazie all’eliminazione di alcune procedure:

- Il tubo non va misurato prima del taglio

- Dopo il taglio del tubo, non c’è da smussare

- Per l’innesto del tubo non c’è da lubrificare

- Nessuna smussatura ne lubrificazione

I rimasugli da taglio non permettono un corretto inserimento e possono causare danni alla guarnizione o l’uscita dalla sua sede nel bicchiere. Con POLO-KAL 3S MT non serve alcuna smussatura dopo il taglio -anche se imperfetto- e si innesta senza l’ausilio di alcun lubrificante.

- Senza fatica è un piacere – Lavorare facendo poca fatica è impagabile e con POLO-KAL 3S MT si alleggeriscono notevolmente tempi e sforzi nell’installazione

- Passa dove altri non riescono – Il bicchiere ridotto, a parità di portata idraulica e diametro interno, permette il transito a solaio e parete in spazi più stretti

- Più pulizia e velocità di posa – Evitare la smussatura, evitare la lubrificazione, evitare la misurazione, semplificano e accelerano i tempi d’installazione

- Completo e 100% compatibile – Gamma diametri da 50 a 160 mm. perfettamente compatibile con tutte le altre marche

Al sistema in polipropilene POLO-KAL 3S MT sono associati tutta una serie di accessori utili alla realizzazione degli impianti di scarico, tra i quali:

- Valvole per la ventilazione dello scarico

- Valvole antiriflusso

- Sistemi tagliafuoco (manicotti – bande – sacchetti)

- Guaine desolidarizzanti monostrato

- Lastre fonoisolanti a triplice strato

- Collari di fissaggio e ancoraggio delle tubazioni

La speciale composizione del sistema POLO-KAL 3S MT determina caratteristiche di robustezza e resistenza anche in situazioni ambientali critiche (freddo rigido o caldo estremo). Inoltre, in caso di urto o foro accidentale, il sistema può essere riparato velocemente tramite termosaldatura praticata da mano esperta con apposita attrezzatura.

- Tubi in PP-C / Porolen / PP-C e raccordi in PP-C / MV. I materiali che compongono il sistema POLO-KAL 3S MT sono completamente riciclabili e realizzati in assenza di alogeni, cadmio e metalli pesanti.

- La temperatura del fluido evacuato all’interno del sistema può raggiungere per un breve periodo di tempo i 98 ° C, mentre per il lungo periodo la temperatura può raggiungere i 95 ° C

- Rigidità anulare pari a 4,0 kN / m² (SN4 secondo EN 1401)

- Coefficiente di dilatazione lineare pari a 0,08 mm / mk

- Resistenza al fuoco in Classe D-s2, d1 (in accordo alla EN 13501-1)

- Livello acustico <10 dB / (A) Lin rilevato in laboratorio in ambiente di prova con 2 piani di caduta e fonometro posizionato al piano più basso, con portata di scarico di 2 litri / secondo (pari a 1 cassetta wc) e collari di fissaggio POLO-KAL dB+

- Diametri di 50-75-90-110-125-160 mm.

- Peso di Kg. 2.380 per un tubo Ø 110 mm. da 1 bicchiere della lunghezza di 1 metro

- Per l’impiego del Polipropilene in presenza di sostanze chimiche contenute nel fluido evacuato, osservare con attenzione quanto prescritto nella relativa TABELLA di riferimento

- Garanzia di 20 anni contro i difetti di fabbricazione

Approfondisci il quadro normativo italiano e scopri le regole tecniche per una corretta progettazione ed installazione a prova di contestazione acustica. Per evitare disturbi acustici e migliorare il comfort abitativo, nulla deve essere lasciato al caso!

Scopri di più