POLO-KAL NG

POLO-KAL NG

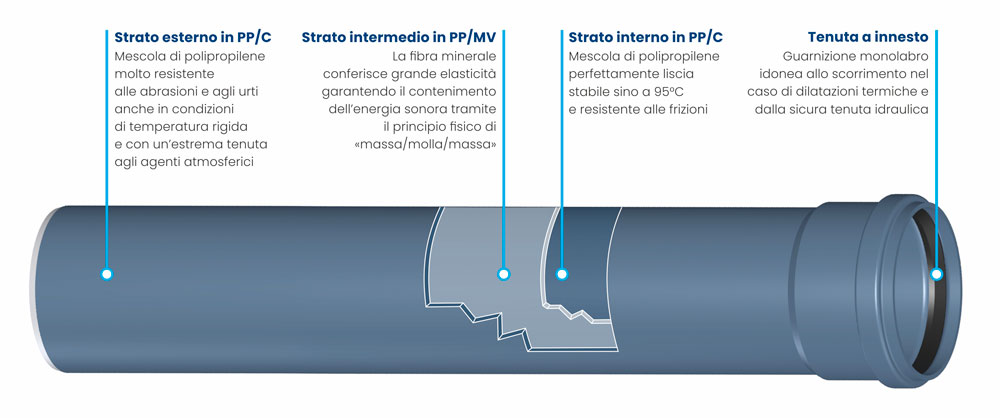

Dal 1995 il primo sistema di scarico insonorizzato in polipropilene (PP) di colore blu RAL 5014 coestruso a 3 strati. La più ampia gamma disponibile con diametri da 32 a 250 mm è composta da tubazioni e raccordi rinforzati con cariche minerali (MV) che conferiscono al sistema ottime doti di isolamento acustico, resistenza all’impatto, alla corrosione, all’abrasione e all’aggressione di sostanze chimiche disciolte negli scarichi civili ed industriali.

Sistema per lo scarico dei reflui conforme alla EN 1451-1 in Classe BD (all’interno del fabbricato e all’esterno, nonché interrato) idoneo per impianti in edifici nei quali è richiesta conformità in materia di isolamento acustico a destinazione residenziale, industriale e commerciale, pubblici e ricettivi come ospedali, case di riposo e RSA, alberghi, scuole, luoghi di culto. Il sistema POLO-KAL NG è idoneo anche per la realizzazione di impianti di VMC (Ventilazione Meccanica Controllata), impianti di geotermia, areazione, estrazione, aspirazione polveri, impianti con spinta in pressione dei reflui (pompe di rilancio oppure trituratori tipo Sanitrit).

POLO-KAL NG FUMI

Le doti fisiche e meccaniche -oltre alle straordinarie prestazioni fonoisolanti- di POLO-KAL NG hanno trovato applicazione anche nell’ambito dell’evacuazione dei fumi generati da caldaie a condensazione e nell’evacuazione delle condense prodotte dalle cappe cucina. Il sistema POLO-KAL NG FUMI copre un range di diametri da 110, 125 e 160 mm. in abbinamento a guarnizioni speciali in EPDM di colore nero ed è stato certificato CE da KIWA in accordo alla norma di riferimento EN 14471:2013+A1:2015. Per la corretta posa di POLO-KAL NG FUMI, si raccomanda di seguire attentamente le indicazioni riportate nelle Istruzioni d’installazione.

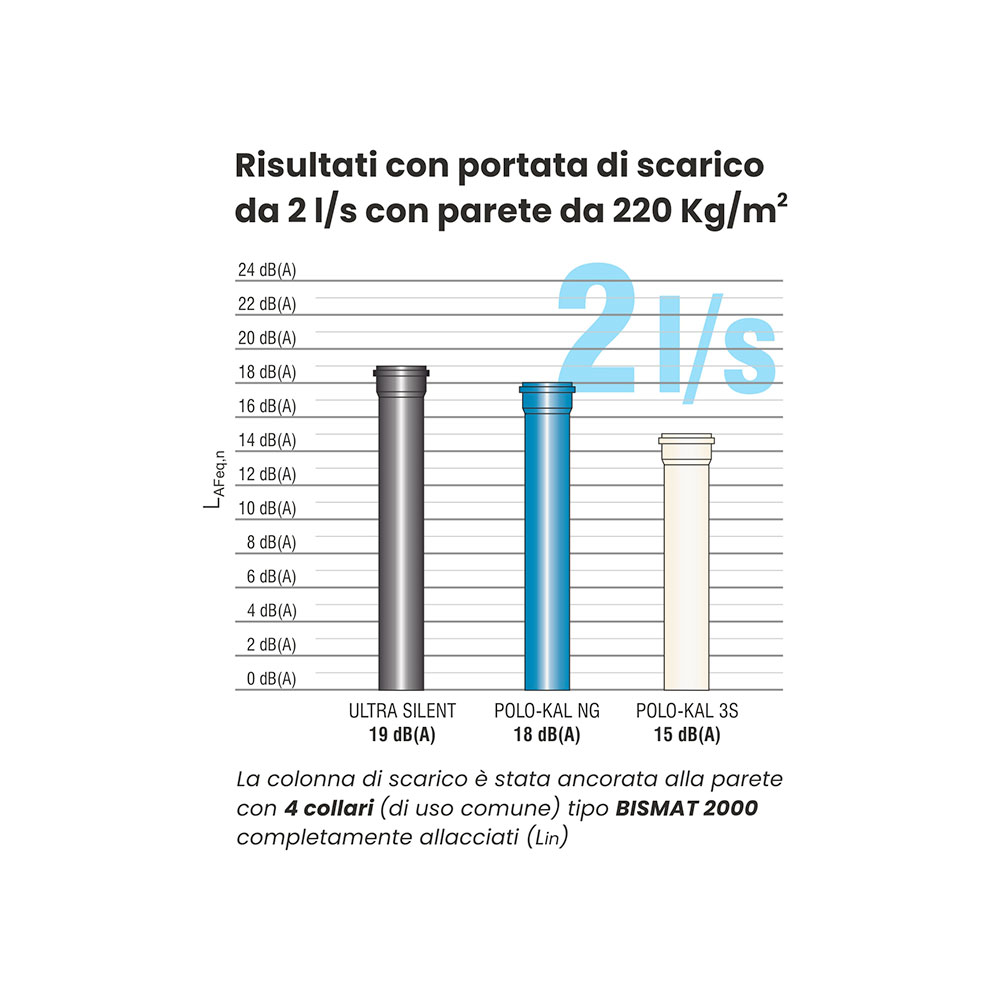

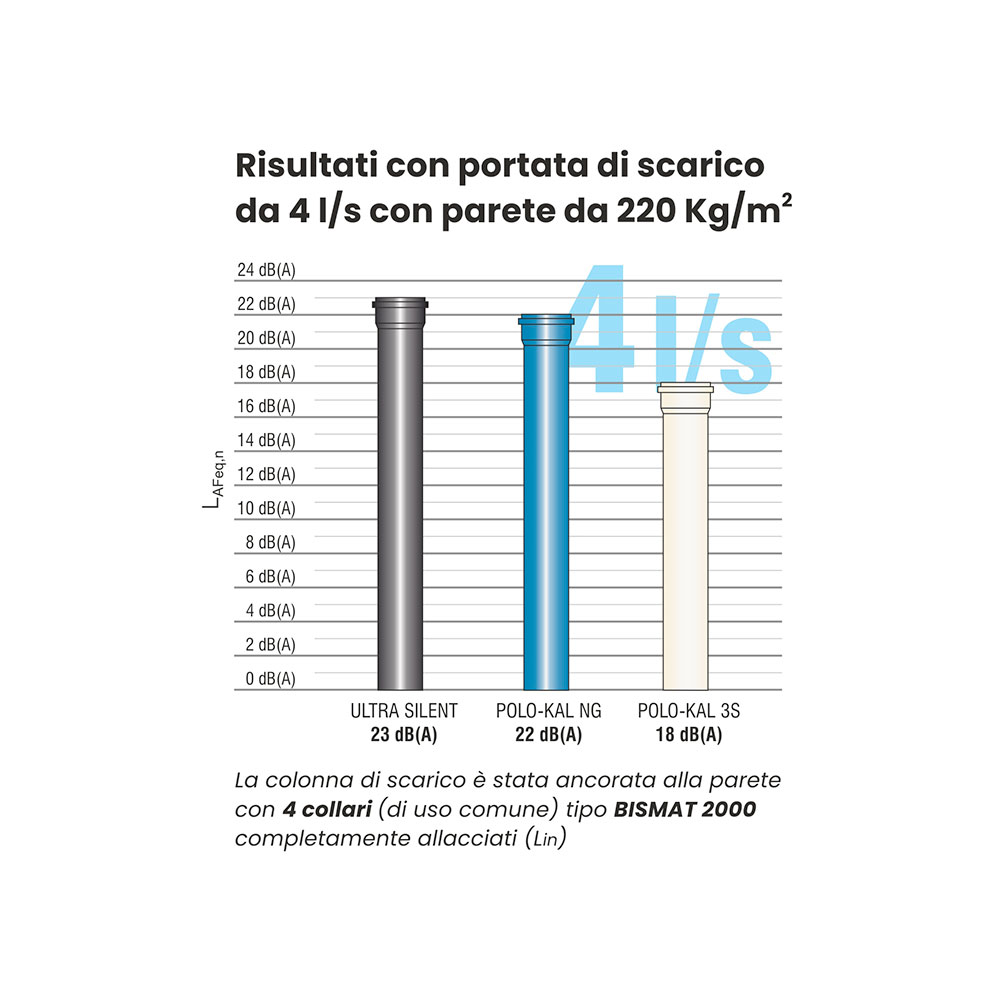

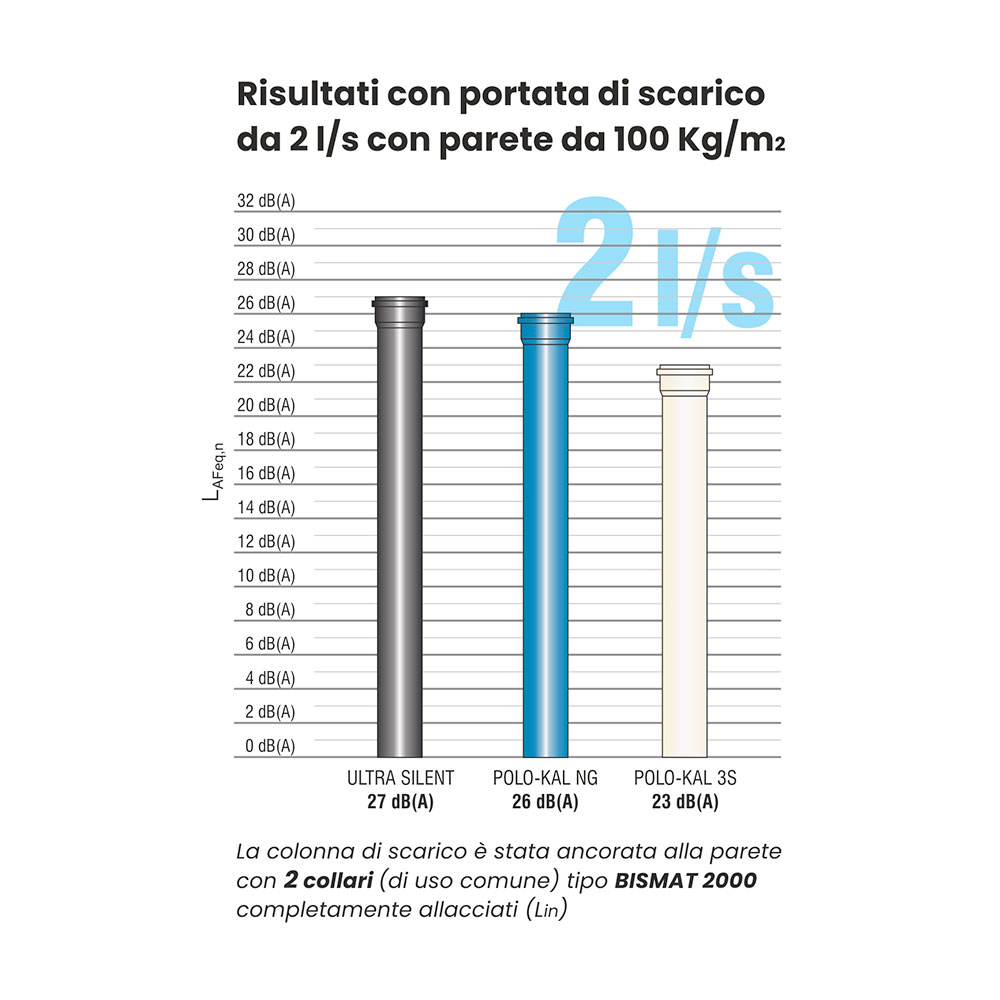

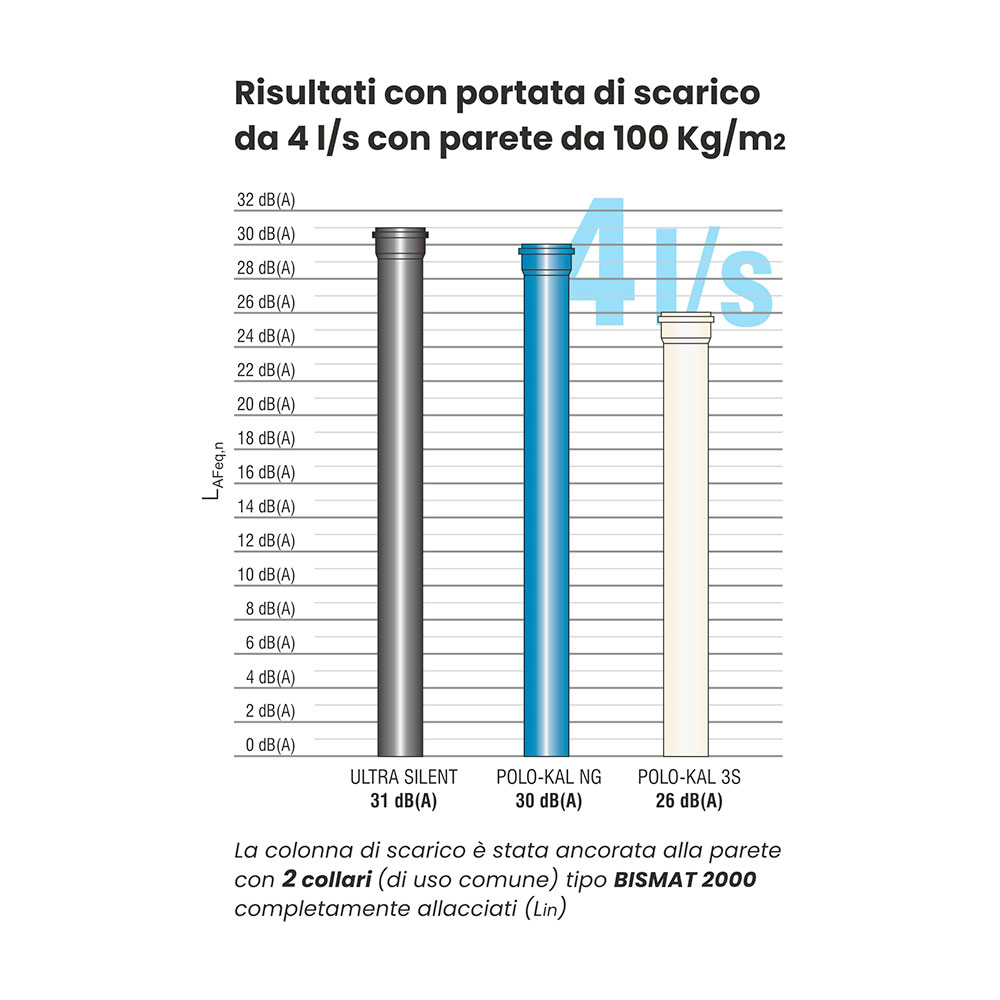

Il sistema di scarico idrico POLO-KAL NG può essere dimensionato secondo quanto prescritto dalla norma di riferimento progettuale, la UNI EN 12056-2. Secondo tali prescrizioni, per la realizzazione della ventilazione del sistema di scarico, possono essere utilizzati tubi e raccordi del sistema POLO-KAL NG o, in alternativa, valvole di ventilazione BAMVENT. In osservanza al DPCM 5/12/1997 sui requisiti acustici passivi all’interno degli edifici (Legge vigente in Italia), il sistema di scarico idrico POLO-KAL NG offre elevate prestazioni di fonoisolamento certificate in accordo alla EN 14366 presso l’Istituto Fraunhöfer di Stoccarda.

Sistema robusto e pratico da installare grazie alla giunzione con innesto, assicurata da guarnizione elastomerica. La connessione con bicchiere garantisce l’adeguato spazio per eventuali dilatazioni dell’impianto con una tenuta affidabile e garantita nel tempo. Il sistema in polipropilene POLO-KAL NG è compatibile alla connessione con altri materiali plastici in PP/PE-HD/PVC nei diametri standard.

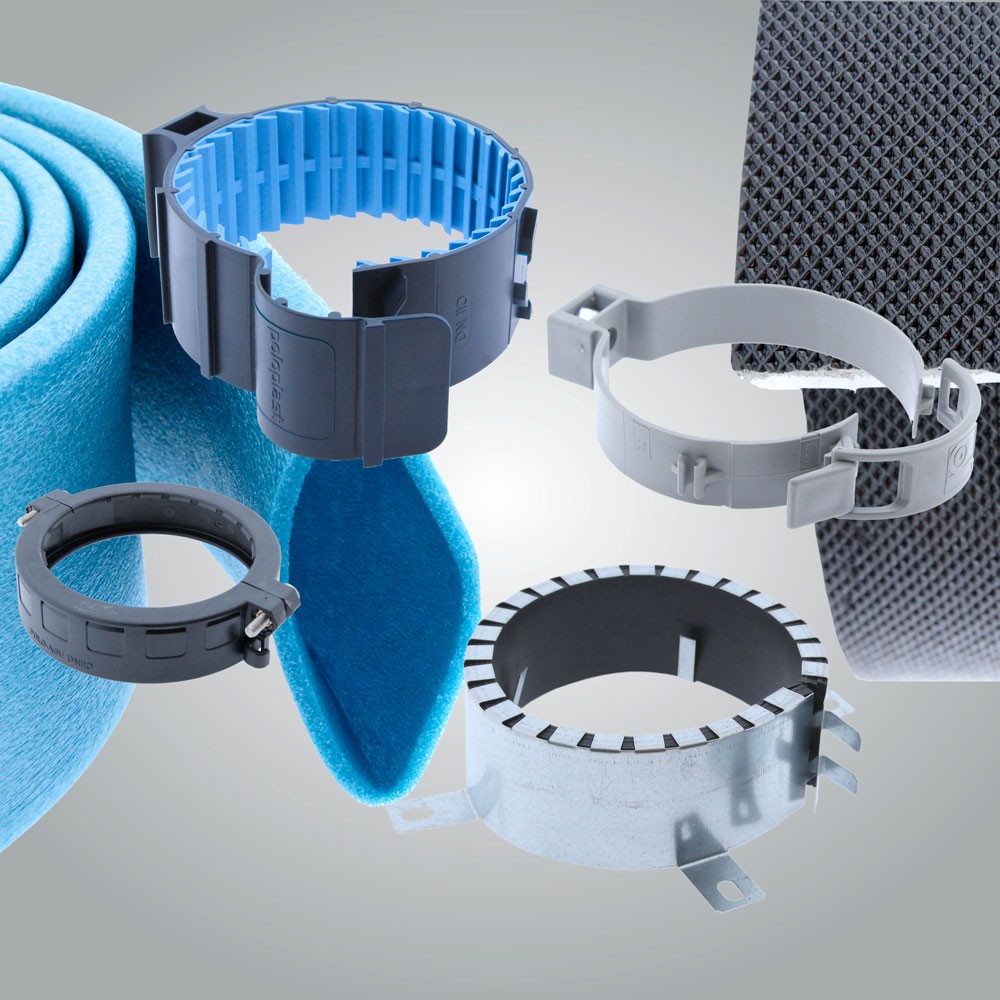

Al sistema in polipropilene POLO-KAL NG sono associati tutta una serie di accessori utili alla realizzazione degli impianti di scarico, tra i quali:

- Valvole per la ventilazione dello scarico

- Valvole antiriflusso

- Sistemi tagliafuoco (manicotti – bande – sacchetti)

- Guaine desolidarizzanti monostrato

- Lastre fonoisolanti a triplice strato

- Collari di fissaggio e ancoraggio delle tubazioni

- Collari di tenuta antisfilamento

La speciale composizione del sistema POLO-KAL NG assicura doti di assoluta robustezza, soprattutto in situazioni ambientali di freddo rigido, con una resistenza all’urto (testata in laboratorio) sino alla temperatura di -20°C. Inoltre, in caso di urto o foro accidentale, il sistema può essere riparato velocemente tramite termosaldatura praticata da mano esperta con apposita attrezzatura.

- Tubi in PP-C / MV / PP-C e raccordi in PP-C / MV. I materiali che compongono il sistema POLO-KAL NG sono completamente riciclabili e realizzati in assenza di alogeni, cadmio e metalli pesanti.

- La temperatura del fluido evacuato all’interno del sistema può raggiungere per un breve periodo di tempo i 98 ° C, mentre per il lungo periodo la temperatura può raggiungere i 95 ° C

- Rigidità anulare pari a 6,0 kN / m² (SN6 secondo EN 1401) sino al Ø 160 mm. e pari a 8,0 kN / m² (SN8 secondo EN 1401) sui Ø 200 e 250 mm.

- Coefficiente di dilatazione lineare pari a 0,05 mm / mk

- Resistenza al fuoco in Classe D-s2, d1 (in accordo alla EN 13501-1)

- Livello acustico pari a 22 dB / (A) Lin rilevato in laboratorio in ambiente di prova con 2 piani di caduta e fonometro posizionato al piano più basso, con portata di scarico di 4 litri / secondo (pari a 2 cassette wc scaricate contemporaneamente) e collari di fissaggio di uso comune normalmente in dotazione agli installatori idraulici (tipo BISMAT 2000)

- Diametri di 32-40-50-75-90-110-125-160-200-250 mm.

- Peso di Kg. 1.490 per un tubo Ø 110 mm. da 1 bicchiere della lunghezza di 1 metro

- Per l’impiego del Polipropilene in presenza di sostanze chimiche contenute nel fluido evacuato, osservare con attenzione quanto prescritto nella relativa TABELLA di riferimento

- Garanzia di 20 anni contro i difetti di fabbricazione

-

Scheda Tecnica

Download -

Manuale Tecnico 2022

Download -

Comparazione sistemi di scarico Bampi

Download -

Listino Prezzi 01-2024

Download -

Dichiarazione di Prestazione CE/FUMI

Download -

Certificazione FUMI - KIWA/CE EN14471

Download -

Istruzioni d'installazione POLO-KAL NG FUMI

Download -

Resistenza alle sostanze chimiche

Download -

Descrizione Capitolato

Download -

Dichiarazione Garanzia

Download

Approfondisci il quadro normativo italiano e scopri le regole tecniche per una corretta progettazione ed installazione a prova di contestazione acustica. Per evitare disturbi acustici e migliorare il comfort abitativo, nulla deve essere lasciato al caso!

Scopri di più